Aerospace Fabrications of Georgia, Inc. News

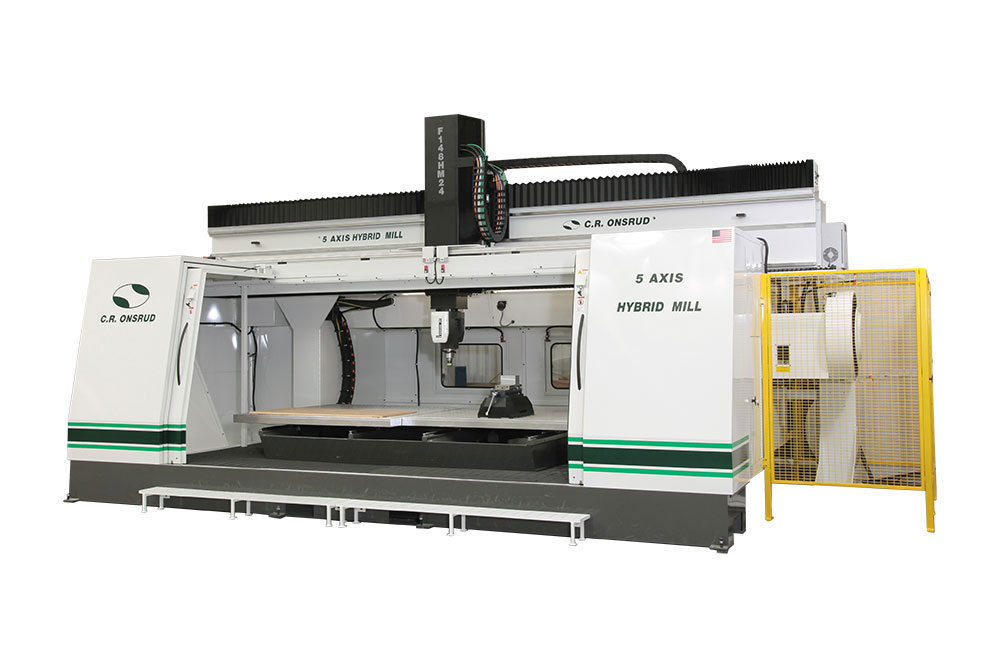

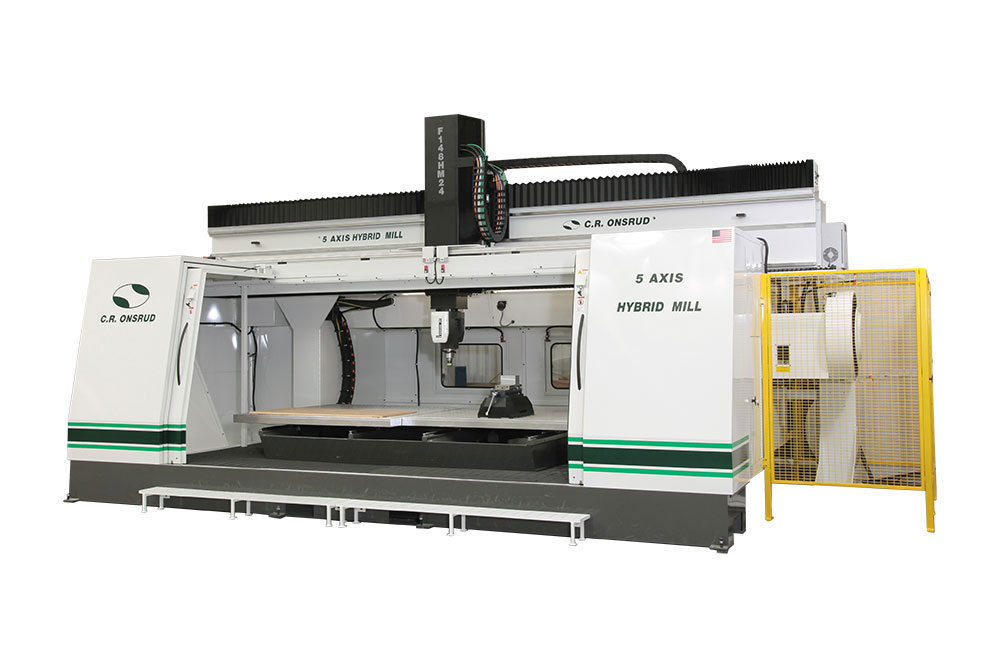

New 5-Axis Hybrid Milling Machine

by Adam Grizzle | February 27, 2019 AFG is taking delivery of our first C.R. Onsrud 5-Axis Hybrid Mill on March 8th! With a 6' X 12' work envelope, this will greatly increase our part size capacity. The machine specifiactions are as follows:  41"Z x 73.75"X x 224.68"Y (resulting in a 6'X12' work envelope)33HP-20,000RPM HSK-63A SpindleFanuc 31i-B5 Machine Controller24 Position Quick Change ATCThrough Spindle Coolant SystemRenishaw Probe and Tool Setter System

Certificate of Registration

by Adam Grizzle | January 31, 2018

AFOG just received our Certificate of Registration which certifies our quality system to AS9100D and ISO 9001:2015

New Hydroform Machine

by Adam Grizzle | June 27, 2013 AFG is taking delivery of our second Personal Press PHP-3070 (30" X 70" work envelope) hydroform press on June 28, 2013. This will greatly increase our load and part size capacity. The machine specifiactions are as follows: 1,100 ton forming30 x 70 inch forming envelope5 inch max form block height6 inch daylightHMI with variable pressure, dwell, and cycle counter20 inch diameter cylinder (2)16 inch diameter ram (2)120 gallon hydraulic reservoir80 durometer urethane forming box30 second cycle timeone button semi-automated controllight curtains + hard guard

TECH DEVELOPMENT; Georgia at Forefront of Drone Technology

November 27, 2012

The abundance of work in Georgia has resulted in some interesting cross-pollination. For example, Alley's company designed a drone to test aerodynamic technologies to increase fuel efficiency in commercial aircraft. The state matched his investment of $50,000. NASA contributed $750,000. Aerospace Fabrications of Georgia helped with parts. Georgia Tech did wind tunnel analysis...

Read more. Read more.

Boeing Bronze Level Supplier 2012

by Rene Pizzaro | Jan 17, 2012

AFG is currently holding a Boeing Overall Supplier Performance Rating Level of Bronze!

99.67% Quality Rating

97.91% On-Time Delivery Rating

Gulfstream's Preferred Supplier 2010

by Rene Pizzaro | Dec 12, 2011

June 2011 - AFG was awarded Gulfstream's 2010 Preferred Suplier of the Year.

AFG was the only Gulfstream supplier to score "GREEN" in all 4 evaluation categories!

Gulfstream's Preferred Supplier 2009

by Rene Pizzaro | Dec 12, 2011

June 2010 - AFG was awarded Gulfstream's 2010 Preferred Supplier of the Year.

Recognized by GAC for our excellent quality record and on-time delivery.

Aluminum Heat Treat Facility

by Stephanie Andersen | Aug 22, 2011

(click on thumbnail to enlarge)

Aluminum Heat Treat Facility

AFG is now offering full Heat Treat services to new and existing customers. Currently, the heat treat facility is separate from AFG's main manufacturing facility but is only minutes away. In 2012, we expect to move this facility to our main plant. The equipment is fully computer controlled and automated and qualifies as one of the most state-of-the-art heat treat systems in the world. The system control was custom-built by company CEO Adam Grizzle. The services offered include solution heat treat, heat age, and check and straighten services for most types of aluminum. The facility is currently fully operational and is certified to NADCAP, Boeing, Lockheed-Martin, Airbus, HondaJet, Goodrich Aerospace, Sikorsky, and Gulfstream Aerospace Corporation, and AMS 2750. Different industries require different levels of certifications. Please contact the facility supervisor (Keith Richardson) for more information regarding this service, or you may contact Keith directly at 770.505.8801 X-123 or email . Please check back as more information becomes available.

Facility Expansion

by Stephanie Andersen | Aug 22, 2011

AFG's new expansion began in December 2008 when we purchased 5 acres of developable land adjacent to our property. The first phase of additions added 23,000 sq.ft. to our existing facility. This effectively tripled our manufacturing area, allowing us to venture into new manufacturing technologies like composite manufacturing. With the first phase we expect to employ an additional 60 personnel.

Facility Expansion

|

Facility Blueprint

|

Completed Expansion

|

The project was completed in July 2010. And finally, the satellite has passed over us, so here is a shot of our new facility!

100th C-17 Celebration

by Adam Grizzle | Oct 22, 2002(click on thumbnail to enlarge)

Saxby Chambliss, U.S. Senator October 2002 -- Saxby Chambliss, U.S. Senator (R - GA) visits Aerospace Fabrications of Georgia, Inc. to celebrate the 100th ship set of the Boeing C-17 aircraft, which AFG particiated in manufacturing. In October 2002, Boeing delivered the 100th C-17 aircraft to the United States Air Force. AFG is a preferred supplier for the C-17 program and was one of twenty-four suppliers selected by Boeing to host a celebration at its facility. The celebration at the AFG facility took place on Tuesday, May 14th. Some attendees included: U.S. House Representative (now U.S. Senator) Saxby Chambliss, Georgia Senator Nathan Dean, Dewey Pendley Hiram Mayor and Boyd L. Austin Jr, Mayor of Dallas.

New Facility

Back to top |

Print This Page

Print This Page